Clounagh Technology and Design

Year - 9 USB Mood Light Project.

In this page you will find all the information you need to complete the Mini Light project.

-

In this section the components are soldered onto the pre-drilled PCB board.

-

The photos below you can see the circuit before any components were inserted or soldered onto it.

-

This side of the board has tracks of wire etched on to it and they conduct the current around the circuit.

-

In the photos below you can see the circuit at various stages of manufacture.

-

In order to make the battery clip secure, the red and black wires are fed through a hole before being soldered. This means that the battery clip should not pull out easily.

For this circuit to work you need to input a number of different components.

-

1x LED

-

1x Resistor

-

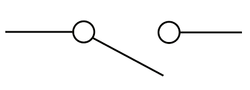

1x Switch

-

1x USB Power supply lead

Images for the circuit components and their symbols are shown below.

Tools required to build a circuit

Below are images, names and descriptions of the tools needed to manufacture a circuit.

Manufacturing The Housing

The housing for the Mini Light project is designed to hold the circuit. It was made from 1 piece of acrylic and a square of Norway Spruce wood.

-

To begin, the edges of the acrylic was cleaned using wet and dry sand paper. Once the edges were free from scratches the polisher was used to buff the edges to a nice smooth finish.

-

A template was then used to mark out the positions of the holes. A cordless drill was then used to drill a hole in each location.

-

The line bender was then used along with 2 bending jigs to bend the housing to shape.

-

The piece of Norway Spruce was then cut in half making two triangles. They were then stuck together using double sided tape.

-

The pieces of Norway Spruce were then sanded so they were the same shape/size.

-

The housing was then assembled and the circuit was inserted into the housing to complete.

See images below

Blank Circuit BoardThis is the circuit board before any components were added. |  Circuit with componentsThe components were added to the circuit board. Remember some components need to be inserted a particular way to work properly! |  Soldered CircuitThis is an image of the circuit with each of the components soldered in place. |

|---|

Resistor Circuit Symbol |  Switch Circuit Symbol |  LED Circuit Symbol |

|---|---|---|

USB Power Lead |